Products/Industrial Sewing/Flat Seamer

Siruba D007R

D007R SERIES

Left hand side fabric trimming before hemming. For sleeve opening and bottom of underwears, T-shirt, or sportswear, etc…

Number of Needles

4

Number of Thread

6

Needles Gauge

4.8/5.2/6.0/6.4

Overedge Width

1.2-4mm

Differential Feed Ratio

1:0.7 – 1: 1.5

Stitch Length

1.6 – 2.5mm

Presser Foot

8 mm

Needle Nro

FL X 118GCS

(4 PCS)

Maximum Sewing Speed

4,200 S.P.M

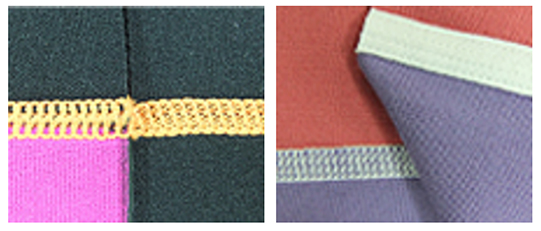

D007R series, 4 needle, 6 thread, feed-off-the-arm, top and bottom cover stitch machine. This machine is suitable for overlapping such as joining of high quality under wear, sport wear and inseaming of brief. Equipped with one side cut or both side cut trimmer, this system guarantees at shape neat finish completely, in order materialize versatile applications from thin to heavy materials such as inseaming of brief’s cross seams. Design of this feed-off-the-arm is perfect for tubular garments.

Features

High Efficient Patented Direct-Drive Design

Compact servo-motor directly drives main shaft with special connector design. It features less weight, agile drive, anti-vibration, low noise, powerful output and precise seaming. Eventually, more cost-saving and integrable electro-control attachments effectively elevate sewing advantage.

Fully Coverstitching For All Lapseamer Series/strong>

Unique mechanism design to deal with wide range fabrics fulfills the sewing request for top and bottom plies lapseaming, going fully to both left and right edge of the stitch.

Patented Electric Presser Foot Lifter Mechanism

The Solenoid smartly concealed in holding base, saving pneumatic volume and accessories, for less weight, anti-vibration, low noise, well balanced body and tidy looks, resulting in time-saving, labor-saving, and higher productivity.

Special Fabric Trimmer Design

Unique fabric trimmer with special material and mirror finish, resulting in frictionless, sharp & durable trimming to enhance sewing quality.

Minimum Cylinder Design

150mm circumference at the needles allows for sewing small tubular work, such as the sleeves seaming of kid’s wear.

Maximal Operation Space Design

Brand-new patented holding base design, providing maximal operation space and saving time to take fabrics, enhances efficient operation and effective sewing.

Functional Presser Foot Mechanism Design

Various functional presser feet (Gauge Sets) fulfill specific sewing requests, such as sewing diving suit, panty hose, attaching folded / woven tape, cross seaming of taping, binding or overlock seam and general seaming.

Floatable Presser Foot Design

Fitted with various presser foot shoes in different models for a wider range application on specific fabrics, such as heavy/light, spandex, smooth & soft, delicate materials, to fulfill most kinds of sewing requests.

Improved Sealed Thread Handling Set

Sealed thread tension control knob design, preventing from exceptional winding, makes sewing smoother and stabler.

Brand-New Automatic Lubrication System

Special “Forced Lubrication” and “Forced Oil Collect” system with filter enhance machine lifetime and possibly eliminate oil stains to qualify sewing performance.

See More

Preview Siruba D007R

| Brand |

|---|