Products/Industrial Sewing/Overlock / Safety Stitch

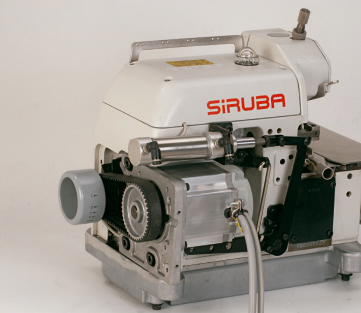

Siruba 747QD-514M2-24/ECA

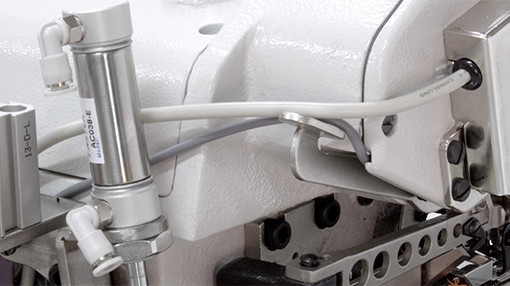

ECA PNEUMATIC TYPE TAPE/THREAD CUTTER

SIRUBA’s re-evolution on EC device! Eliminating the control box and driven by the powerful computerized system to control the cutting movements is an implementation of “single machine automation” concept. Advanced sensor inspects the completion of sewing work and initiates cutting without time lag.

Number of Needles

2

Number of Thread

4

Needles Gauge

2

Overedge Width

4 | 6

Differential Feed Ratio

0.7-2

Stitch Length

3.6

Presser Foot

5.5

Needle Nro

DCX27#11

Maximum Sewing Speed

7,500 S.P.M

For regular seaming on light to medium fabric.

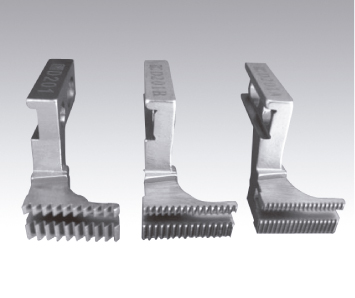

A: Single row feed dog.

B: For regular seaming on light to medium fabric.

C: Mock 516 seaming For regular seaming on light to medium fabric.

D: For regular seaming on light to medium fabric.

Specially suitable for small production workshop, and fashion design studio. A variety of five different sewing types by changing number of needle and looper.

ECA PNEUMATIC TYPE TAPE/THREAD CUTTER

SIRUBA’s re-evolution on EC device! Eliminating the control box and driven by the powerful computerized system to control the cutting movements is an implementation of “single machine automation” concept. Advanced sensor inspects the completion of sewing work and initiates cutting without time lag.

ECA is pneumatic type, and ECB is electric type, compatible with air suction slot, which makes the operation more smoothly.

1.Manual, semi-auto and fully-auto operation mode, attached the switch keys, and could be adjusted by the panel.

2.Mistake-proof protection device: One sensor equipped near the trimmer. If the sensor is blocked, the trimmer is deactivated effectively for avoiding from cutting the fabric.

3.Manual trimming compensation stitch key: If the thread is not cut due to the operation, it can be done by the key.

4.Under the manual mode, it could be fully backward pedaled to cut the thread.

5.For those special fabrics such as mesh fabric, mercerized cotton etc, the stitches are easily accomplished as well as the trimming by the professional computer controlled without mistake-trimming.

Features

Patented high efficient & energy-saving direct-drive design (700KD)

– Integrated machine frame design.

– Built-in servo motor. Fast responsiveness, quiet, and low vibration. Easy speed setting.

– Built-in synchronizer, hand wheel is free of obstacle.

– Needle position function.

– High efficiency, energy saving, intergrated electrical system.

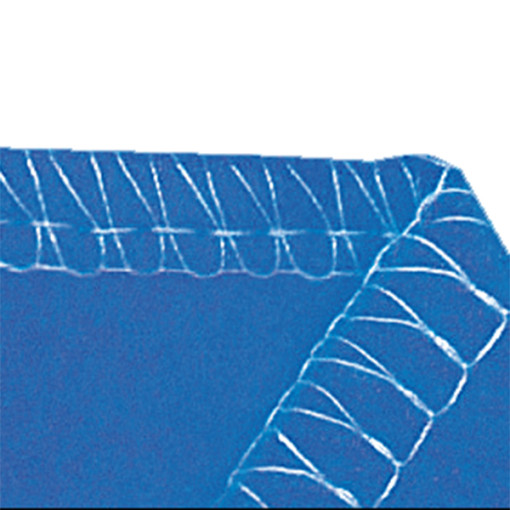

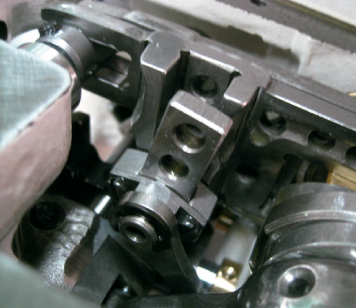

Sealed type direct drive needle bar mechanism

– Dust free and oil-leakage-free are due to entirely sealed needle bar section design.

– Direct drive needle bar system leads to high speed and long durability. No driving loss of connecting-rod-drive needle bar system.

Active lubrication system

Needle bar and upper looper mechanisms are applied active oil supply and entirely sealed vacuum oil return system. The new system exceeds the traditional oil supply of rope type and dropping type.

Patented feed dog mechanism oil proof system

New double-lip type wiper is added to support the original double wiper. Oil proof function is upgraded.

Direct drive feeding mechanism

Direct drive mechanism prevents overdoing of differential feeding. No need to adjust the differential feed dog. No drive loss of connecting rod and type feeding mechanism.

New fabric trimmer mechanism

Low axis knife holder prevents cloth rolls up after trimming.

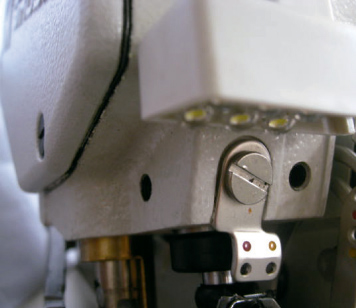

Patented integrated built-in lighting (Optional)

– Integrated built-in LED light design is artistic and user friendly.

Feed dog for extra light weight fabric (Optional)

E.g.: D201(standard):Teeth spacing 1.6mm ; D201A(optional):Teeth spacing 0.8mm ; D201B(optional):Teeth spacing 1.0mm

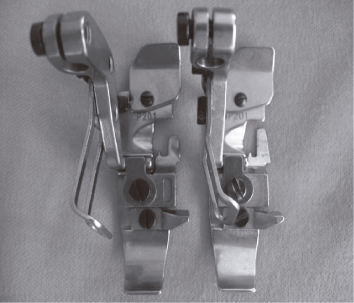

Optional presser foot fingers for better sewing performance: short finger for heavy fabric, long finger for

light fabric.

More user friendly features:

– Needle bar height adjustment without opening machine.

– Lower looper holder fine tune mechanism.

– Chainstitch fine tune mechanism: Open the rare cover to adjust stitch length easily.

– Needle plate thread groove leads to perfect loop.

– 5 cm height sewing area offers better cloth movement.

Electric-eye controlled waste vacuuming system(ET Device) (700KD Optional)

– Save energy. Reduce air compressor’s loading to 40% or more.

– Air suction is activated only when trimming thereby reduce the noise of air suction effectively.

– Does not suction light cloth into the suction trimmer. No need to overrun the seaming for suction trimming. Save

thread consumption and increase operation efficiency.

– Simple, easy, and user friendly.

See More

| Type | Description | Link |

|

Manufacturer Product Catalog | View |

Preview Siruba 747QD-514M2-24/ECA

| Brand |

|---|