Products/Industrial Sewing/Lockstitch

Speedway SW9000-D4

Energy-saving servomotor is installed in the direct-drive style.

– The direct drive system has been adopted.

– Both the control box and the operation panel are integrated with the machine head.

– Dramatically advanced availability for material.

– Maintainability is improved.”

Application

Light to Mediun Weight

Needle

DB×1 (#14) #14~#18

Stitch Length

5 mm

Presser Foot

By hand : 5.5mm, By Knee : 13mm

Maximum Sewing Speed

4,000 sti/min

Lubrication

Automatic

Energy-saving servomotor is installed in the direct-drive style.

The direct drive system has been adopted.

Both the control box and the operation panel are integrated with the machine head.

Dramatically advanced availability for material.

Maintainability is improved.

Features

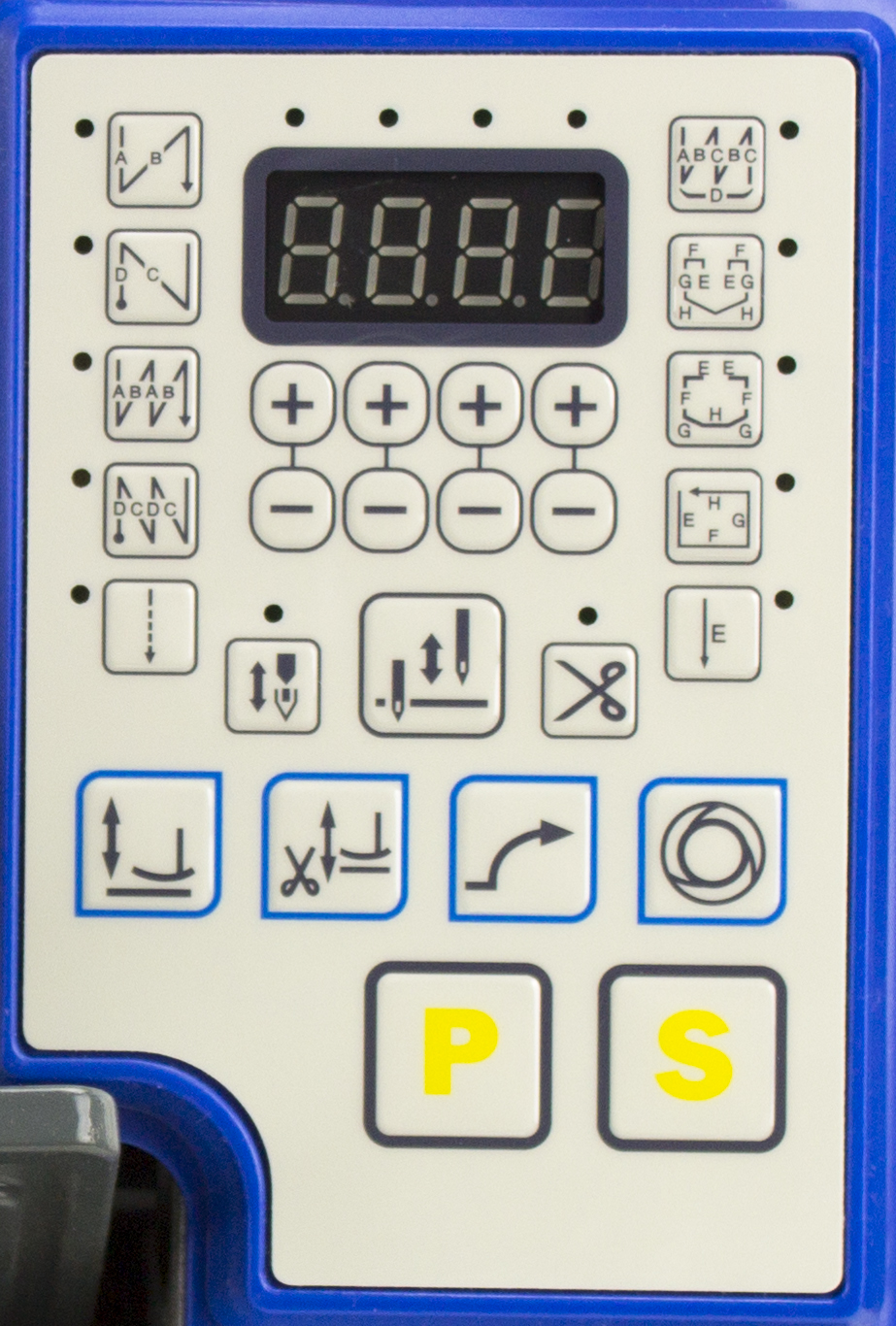

The compact-sized control box and operation panel

Both the compact-sized control box and the operation panel are integrated with the machine head. The machine is provided as standard with the operation panel.

- Automatic reverse-feed stitching

- Double reverse-feed stitching

- Constant-dimension sewing

- Rectangular stitching

- Pocket sewing

- Multi-layer stitching

- Needle up/down compensating stitch

- Automatic sewing

- Soft start

Energy-saving servomotor is installed in the direct-drive style.

The energy-saving and highly efficient servomotor is installed in the direct-drive style to transmit power without loss to the sewing machine, thereby providing improved responsiveness, quicker start-up and increased needle penetration force.

The thread take-up lever which provides a wider sewing range is adopted.

The use of the newly-developed thread take-up lever increases the needle bar stroke (35mm). With this feature, the sewing machine is able to sew many different types of materials ranging from light-weight ones to medium-weight denim.

The new tension spring is adopted.

The new tension spring is adopted to support the sewing of materials which differ in thickness ranging from light-weight materials to medium weight ones.

Newly-developed hook is adopted.

The newly-developed hook is adopted. This hook can handle even a higher-count thread with consistency.

Feed-cam timing adjusting hole.

The adjusting hole is provided on the top of the arm. This hole facilitates adjustment of the feed-cam timing.

Direct-drive type.

Since the sewing machine has no V-belt, the operator needs neither to clean up shavings from the V-belt, nor adjust the V-belt tension.

Thread trimming unit adjusting hole.

Thread trimming unit adjusting hole is provided. Adjustment of the hook timing (temporary fixing) can be carried out without tilting the sewing machine.

Needle bar thread holder.

It does not require the operator to pass the thread through the needle bar, thereby helping reduce the operator’s fatigue.

LED light is provided as standard.

A thinner LED light is provided near the needle entry area. Its illuminance is adjustable steplessly.

See More

| Type | Description | Link |

|

Brochure | View |

Preview Speedway SW9000-D4 (Juki DDL-8100B-7)

| Brand |

|---|