Products/Industrial Sewing/Coverstitch

Juki MF-7523

The machine can be used for the hemming process of the sleeves and bottoms of T-shirts and for the covering process for sportswear and knitwear. The front cover is trimmed to allow operators to bring their hands closer near the needle entry area, thereby increasing work efficiency in the covering process, etc.

Number of Needles

2

Number of Thread

4

Needles Gauge

3.2,4.0,4.8,5.6,6.4mm

Overedge Width

3.2

Differential Feed Ratio

1:0.7~1:2

Stitch Length

1.2~3.6

Presser Foot

5 (8)

Needle Nro

UY128GAS( #10S) #9S~#12S

Maximum Sewing Speed

6,500 S.P.M

The machine can be used for the hemming process of the sleeves and bottoms of T-shirts and for the covering process for sportswear and knitwear. The front cover is trimmed to allow operators to bring their hands closer near the needle entry area, thereby increasing work efficiency in the covering process, etc.

The MF-7500 Series is a newly developed coverstitch machine provided with lots of mechanisms for improving the seam quality.

Features

Thanks to the new feed mechanism, many different types of sewing are achieved.

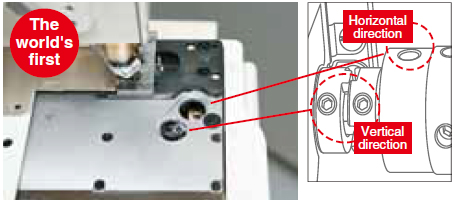

The feed locus can be adjusted externally. The feed locus is now adjustable in terms of the vertical direction and horizontal direction, thereby improving responsiveness to sewing materials.

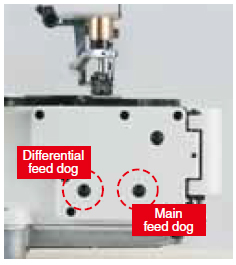

Differential-feed micro-adjustment mechanism.

It is possible to finely adjust the differential feed amount to a best-suited value for the material to be used. The differential feed ratio is constant even if the stitch length is changed.

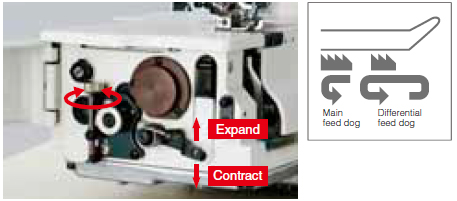

Feed longitudinal position adjustment mechanism.

The longitudinal position of the feed is adjustable. As a result, uneven material feed and puckering that are likely to occur when sewing products made of elastic materials such as foundations are reduced. This means that the machine promises improved responsiveness to elastic materials.

| Type | Description | Link |

|

Manufacturer Product Catalog | View |

Preview JUKI MF-7523

| Brand |

|---|