Products/Industrial Sewing/Zigzag Stitching

Juki LZ-2290A

Computer-controlled, Direct-drive, High-speed, 1-needle, Lockstitch, Zigzag Stitching Machine

A single LZ-2290A Series machine is extremely versatile and can perform many different stitching patterns.

Application

Light to Medium Weight

Max. Stitch Length

5 mm

Max. Zigzag Width

10 mm

Needle Nro

438 (Nm70), DP×5 (#10)

Maximum Sewing Speed

5,000 sti/min,

T-shape stitching: 4,000 sti/min

Lubricating oil

Automatic

It comes in two different models, one with standard specifications and the other with an anti-material slip capability. For both models, there are two subclass models, i.e., the “minute-quantity lubrication type” and the “dry-head type”, which eliminates oil stains on sewing products. You may select the best-suited model from the diversified subclasses according to your applications.

The machine is also provided with a newly-developed operation panel, the IT-100. With this operation panel, you can easily establish settings for stitch shapes and stitches, as well as conduct setup changing, thereby achieving further increased availability./p>

Features

Sewing pattern

The machine is provided with many different stitching patterns.

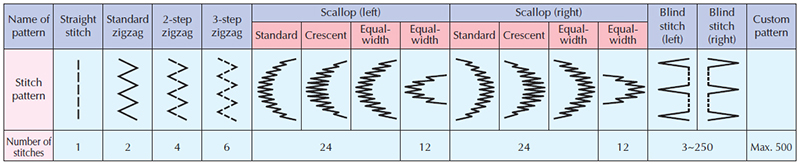

The machine is provided as standard with fourteen different basic zigzag stitching patterns grouped into eight different types. You can choose the zigzag stitching pattern you want directly on the operation panel (IT-100) of the machine body. The zigzag width, needle throw position and number of blind stitches can also be easily adjusted on the operation panel.

A single unit is extremely versatile and can perform straight stitching, standard zigzag stitching, 2-step zigzag stitching, 3-step zigzag stitching, scallop stitching, and blind stitching. As a result, the system is available for a far wider range of applications.

Advanced operation panel IT-100

A liquid crystal display has been adopted. It displays stitch shapes, zigzag width and standard lines with pictographs and settings all together on one screen to improve operability of the panel.

The machine has added capabilities that make the most out of the computer-controlled sewing machine functions, such as program stitching (constant-dimension sewing), cycle sewing and continuous sewing. With these capabilities, the machine is able to respond to sewing in various processes.

Custom pattern data can be stored using the same USB memory.This enables the sharing of custom patterns, not only in one plant, but also among two or more sewing plants, by exchanging data via e-mail systems.

Soft-texture seam quality.

The thread tension mechanism, bobbin case and feed timing have been improved to produce soft-textured seams.

The machine is equipped with a hookdriving shaft-offset mechanism which places the hook-rotating shaft off-center from the center of zigzag stroke of the needle. This mechanism allows the blade point of the hook to catch the needle thread every time regardless of the needle throwing direction. As a result, the machine is immune to sewing troubles such as stitch skipping and thread breakage, annoyances likely to occur with the conventional machine, especially when the needle throws to the right.

For the minute-quantity lubrication type hook, the inner hook is finished with titanium to keep it from becoming hot. The machine requires only a very small quantity of oil. This prevents oil stains on the material and the improves durability of the hook. In addition, the hook configuration is carefully designed to avoid needle breakage.

Wider space under the arm

JUKI has developed a new high-long arm machine head one size larger than the head for the conventional lockstitch machine. With its wider area under the arm, the machine permits easy handling of the sewing material for improved operability. The shape of the jaw gives the operator a clear view of the area around the needle.

Reduced noise and vibration

The machine comes with a more rigid and well-balanced machine head frame. This, coupled with the direct-drive method, dramatically reduces the noise and vibration of the machine and helps reduce operator fatigue.

Higher productivity

In the standard zigzag stitching mode with the zigzag width set to 4mm, a frequently selected operating condition, the machine sews at a top speed of 5,000sti/min, that is the world’s highest available speed as a computer-controlled zigzag stitching machine, to increase in productivity.

The maximum zigzag width: 10mm

A zigzag width of as large as 10mm is possible for all types of stitch shapes.

Sewing troubles such as stitch skipping or thread breakage will never occur even when sewing at the maximum zigzag width.

Increased feed amount

Since the machine supports the feed amount as large as 5mm, this single machine is able to handle various feed types from standard feed to coarse feed. The coarse feed is effective when sewing stretched elastic tapes in processes such as elastic tape attachment to waistbands in shorts. (For the anti-material-slip type machine, the maximum feed amount is 2.5mm.)

The stitch dial is a stepless adjustable type. This enables fine adjustment of the feed amount.

Excellent maintainability

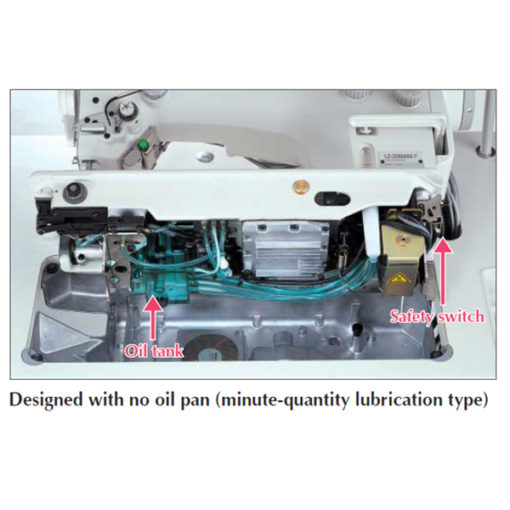

The machine is structured without an oil pan. Oil is supplied from the oil tank installed on the machine to the hook and needle bar.

In addition, the oil hole is located on the machine arm. This is quite helpful to female operators; since oiling can be carried out without tilting the machine head.

Time and effort are conventionally required to remove the knee lifter and cover. This means the machine head can be easily tilted when cleaning the machine or performing maintenance.

A safety switch is mounted on the machine head. If the machine is tilted with the power on, the safety switch is activated and disables the machine operation. In this disabled condition, the machine will never run even if you depress the foot pedal.

See More

| Type | Description | Link |

|

Product Catalog | View |

Preview Juki ZL-2290A-

| Brand |

|---|